3 good reasons to clean your heavy-duty engine

Economy

Save on spare parts and workshop time

Better performance per litre

Extended engine life

Environment

Better combustion and cleaner exhaust

Improved EGR valve, catalytic converter, and particulate filter

Environmental compliance

Driving pleasure

Smooth engine without judder or knocking

Increased pull and acceleration

Starts all year round

Cleaning the engine system in modern heavy-duty diesel engines will pay off in the long run. Costly downtime and parts replacement can be avoided, and you get a machine that simply runs better.

Developed specifically for heavy-duty

With the introduction of common rail, high-pressure nozzles, EGR valves, and particulate filters, heavy vehicles have become just as vulnerable to soot and coke in the engine as cars.

Bell Add’s Heavy duty range is developed in close collaboration with Danish customers in agriculture, transportation, and other industries where the heavy vehicles must work every day.

We developed the Heavy duty range to provide the best possible chemistry for cleaning the internal parts of large diesel engines.

Today, large modern diesel engines are more technically advanced than ever. As a result, they have also become more sensitive to soot and coke, and the machines require ongoing maintenance to function optimally and meet environmental requirements.

Many workshops and agricultural contractors use Bell Add to clean and maintain the biggest engines.

Job satisfaction and good economy

A clean engine is an efficient engine. Getting ahead of the problems will pay off in the long run, and when your machine is in top shape, you’ll feel it right away! Like when it starts right up, with no shudder or engine knock, and when you kick the gas and there’s plenty of power to spare.

When soot and coke no longer block for a clean combustion, the pull is improved, and fuel efficiency maximized. At the same time, the impact on the environment is reduced – because a clean and efficient engine pollutes less.

The Bell Add Heavy duty range is used for large or small service, pre-inspection and when changing oil or pollen filters. Learn more about the products here.

Extended engine life

Bell Add’s Heavy duty range is designed specifically for the unique conditions and challenges of working with modern tractors, construction equipment, trucks, buses, and emergency vehicles.

The lubricating ingredients in Bell Add’s quality detergents reduce friction in the engine’s vital parts, so it’s less stressed in critical situations such as cold starts and driving with many starts and stops. Regularly cleaning the engine extends its lifespan, improves fuel efficiency, and makes the machine a lot more fun to work with.

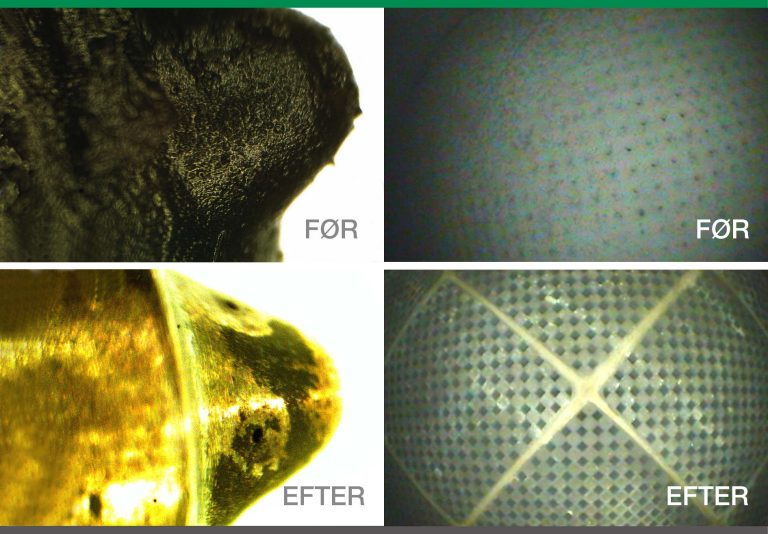

An injection nozzle tip photographed inside the engine using an endoscope camera. At the top, the nozzle tip with deposits, and at the bottom, the same nozzle tip after cleaning. To the right is a particle filter before and after cleaning with Bell Add.

Modern engine systems require a higher level of cleanliness

Thanks to increasingly sophisticated injection systems and engine controls, large diesel engines can now deliver high performance with low fuel consumption and minimal pollution.

Pollution is further reduced by additional systems such as DPF, PCV, and EGR, which recycle exhaust gas as well as oil and fuel vapours back into the engine for combustion. The systems may reduce pollution outside, but inside – in the bowels of the engine – deposits of soot and particles build up.

Specialized cleaners and cleaning machines are used for limited and targeted cleaning tasks in the engine. There are also targeted Bell Add additives that address diesel plague and fuel preservation.

In the workshop

A thorough cleaning of the high-pressure nozzles may be required during an inspection. For this task, Bell Add has developed the Injector Cleaner machine, which is used with the fluid Common-Rail System Cleaner. Also available: Special Bell Add products for cleaning turbo and particulate filters.

Solutions for shared fuelling facilities

It’s a good idea to care for your engine regularly with Bell Add’s additives. This way you can avoid downtime, loss of business, and costly repairs due to sooty machines. If your business has multiple vehicles and shared fuelling facilities, we can advise on the installation of blending systems that add the exact amount of additive to the diesel oil – so you can keep all your machines’ nozzles and systems clean.